about us

For us, building watches is not just business – it is an important part of our lives. To design, construct, manufacture and decorate them by ourselves, to know every single square millimetre in detail, this is the living claim of our manufactory.

Through many years of cooperation with the local and international brands, we have acquired the knowledge and industrial skills to manufacture our own products, which rightly bear the designation of origin „Glashütte“. A small team of highly specialised professionals realises the essential part of the activities in our company from the first pencil stroke to the finished watch.

Today, we are proud to be the smallest independent watch manufacturer in the german watch industry.

design & construction

- construction and development according to full industry standards

- measuring and remodeling of parts and assemblies

- 3D Design and modeling of watchcases, dials, hands, watch parts and complete movements

- programming of certain parts in SolidCam

- producing of detailed technical drawings

- preparation and processing of a series production in small to medium quantities

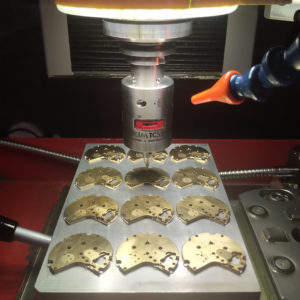

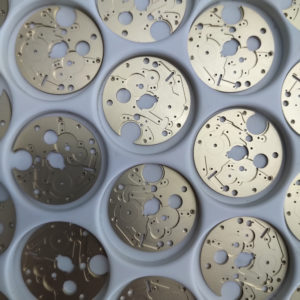

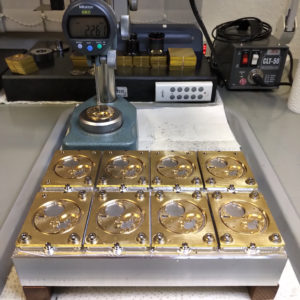

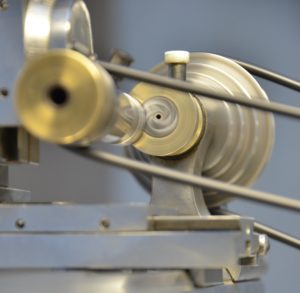

mechanical parts

- CNC production of micro parts up to 5 axles on an industrial scale

- CNC lathe machining components

- eroded components

- conventional milling components

- conventional lathe machining components

- manufacturing of mechanical assemblies

- fully automatic optical measurement

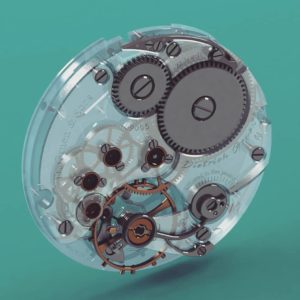

mechanical movements

- central second conversions

- classic and innovative ratchet systems

- fine regulating parts

- indication of day and date

- display of power reserve

- indication of day/night time

- display of time zones

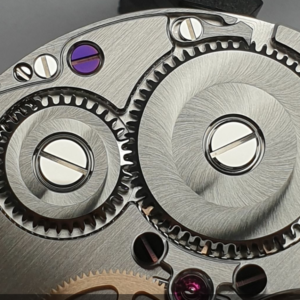

finishing & galvanisation

- straight and circular grindings, bevel polishing, perlages on head surfacess

- solarisation grinding on winding wheels

- genéve stripes on main plates and bridges

- micro sandblasting of components

- thermal blueing of screws and hands

- galvanic coatings in Au, RH and Ni

- individualization of products with custom engravings

assemblies

- assembly and adjustment of mechanical movements

- assembly of dials and hands

- assembly of case and strap components

- testing of power reserve and accuracy

- regulation of movements according to chronometer standards

- testing of water resistance

- complete accompaniment from packing to shipping

watches

- we build our own watches. feel free to have a look at the models on their websites.

- - classic aircraft layout with indexing at 12 o’clock position

- - matt black dial with printed light emitting indicators

- - different representation of the last 10 minutes of an hour

- - differentiated shape of hands for clear time detection

- - Luminova luminous mass for long lasting night readability

- ARES TIMING

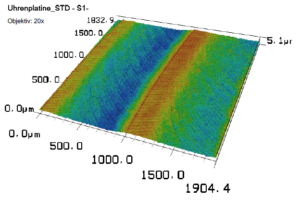

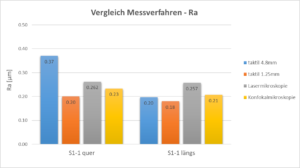

research & development

We conduct research with our partners in the materials and tooling sector to find viable solutions for the environmentally friendly production of watch components.

In cooperation with the Fraunhofer institute and various industrial companies, we develop concepts and technologies for the use of heavy metal-free brass alloys.

the testing and evaluation of hydrocarbon-free cooling lubricants in connection with industrial production stands for a future-oriented, health-friendly way of manufacturing.

contact

-

DKprecisionmechanics / DoKo Feinmechanik

Donat Kornagel

Haupstrasse 12

DE-01768 Glashütte

Tel. +49 35053/321465

fax. was yesterday.

e-Mail: info[at)dkprecisionmechanics.com